Cobots vs industrial robots: Industrial automation has advanced by leaps and bounds, and more and more companies are wondering which option is best: cobots or industrial robots? Both types of robots have key functions in industry, but their differences can determine the success or failure of an implementation. In this article, we clearly explain what cobots (collaborative robots) are, how they differ from traditional industrial robots, and when it is best to choose one or the other.

What is a cobot?

A cobot, or collaborative robot, is designed to work safely alongside humans without physical barriers. They are compact, easy to programme and perfect for repetitive or assistance tasks. Their biggest advantage: human-machine collaboration.

You can find out more about our solutions for collaborative robots in industry.

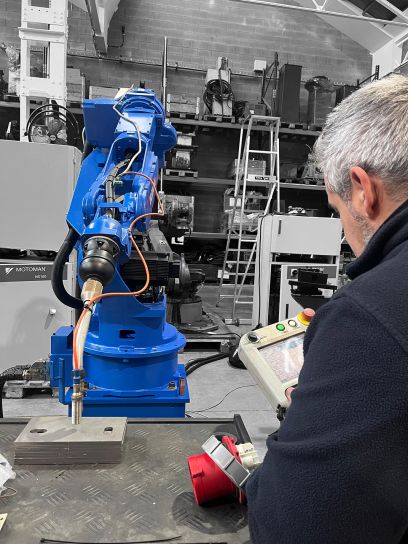

What is an industrial robot?

An industrial robot It is an automated machine with high precision, used mainly in environments where high precision is required. a6> and precision used mainly in environments of mass production mass production. Due to their speed and strength, they usually work in areas separated from personnel, with fences or booths for safety.

You can find out more about our collaborative robot solutions for industry.

At SEMAPRO we develop projects in industrial robotics tailored to your needs.

Diferencias Cobots vs Robots Industriales

Advantages of Collaborative Robots (Cobots)

- Quick and easy installation

- Reduction of repetitive tasks for operators.

- Savings in space and security costs.

- Ideal for all types of businesses

- Possibility of moving it between stations.

Advantages of Industrial Robots

- High speed and productivity in repetitive processes

- High load capacity

- Greater range and power

- Ideal for mass production

- Integration into fully automated lines

Differences by type

Para ayudarte a decidir entre un robot colaborativo (cobot) y un robot industrial tradicional, hemos preparado una comparativa detallada donde analizamos sus principales diferencias: seguridad, velocidad, capacidad de carga, flexibilidad, tipo de producción e inversión inicial.

¿Cobot o robot industrial? ¿Cuál conviene más?

The choice depends on several factors:

- Type of task (welding, pick & place, handling, palletising, etc.)

- Production level

- Available space

- Interaction with operators

- Budget

- Future scalability

If you are looking for flexibility and collaboration, a cobot is ideal.

If you need power and intensive production, an industrial robot is the best option.

At SEMAPRO we analyse each project to offer the solution that truly optimises your production process.

Automate with experts in industrial robotics

En SEMAPRO llevamos más de 20 años integrando soluciones de automatización industrial, robots de soldadura, células robotizadas y robots colaborativos adaptados a cada cliente.

Would you like to know what type of robot suits your company?