On our website you will find information about who we are, our history and the services we offer. Today we would like to explain our work methodology, so that you can learn about the process we follow when developing projects with our clients.

Once the commercial process has been completed and the customer has accepted the quotation, we start working on the solution. Customers come to us with a need, but they are not always clear on how to address it: they need to weld parts, handle other parts, etc. At Semapro, we listen to them and understand their needs in detail.

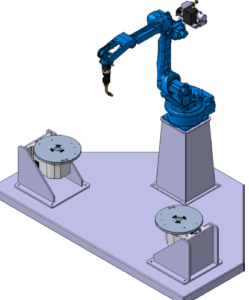

Through a technical meeting, we start working on a 3D design using state-of-the-art software, allowing the client to visualize how their installation will look. This stage is essential, as it allows us to test and adjust aspects that may seem adequate at first, but by seeing them in 3D we can identify necessary improvements.

Once the design (known as the layout or implementation plan) has been approved, it is possible to), we move on to the work phase in the cell. The technical team is responsible for reconditioning the robot, installing its control cabinet and adding the necessary accessories according to the specifications of each cell (positioners, turning tables, track, etc.). A thorough check is carried out to ensure that everything is in perfect condition before moving on to the next phase.

We then start the engineering, adapting the work to the customer’s specific needs and defining the specific functions that the robot will have to fulfill within that cell.

When the robotic cell is ready, which means that it has passed all of Semapro’s internal quality controls, we proceed to the packaging and shipment to the customer’s facilities. A team of technicians travels to the site to carry out the assembly, following the space previously calculated for the installation.

Once the installation has been completed, a final test is carried out again to ensure that everything is working correctly, as we cannot be confident that the transport or installation has not caused any problems. When everything is checked and in perfect condition, we proceed to train the customer’s technicians to ensure that they can operate the cell efficiently.

At Semapro, we are committed to ensuring that every project is completed to the client’s expectations, to the highest quality and in the shortest possible time. We pride ourselves on offering a personalized service, where every detail is tailored to the specific needs of each client. The process we follow when developing projects with our clients seeks not only to meet technical requirements, but also to generate a relationship of trust and satisfaction that lasts over time.

If you have any questions or would like to know more about how we can help you optimise your processes, please do not hesitate to contact us. We will be happy to help you with your next project.